Services

Electrical Services and Maintenance

H&D Electrical specialise in Electrical & Mechanical Building Maintenance for large commercial buildings, industrial properties, retail premises, offices and body corporate buildings.

Whether we are responding to an Emergency fault situation or developing a preventative asset maintenance schedule, H&D Electrical has the experience and technical equipment to complete thorough electrical analysis, routine servicing of controls and components, testing and repairs, fault diagnosis, electrical maintenance, testing and tagging, routine servicing, repairs of all electrical components and/or replacement of electrical systems throughout Brisbane.

A single breakdown in a commercial electrical system can prove to be extremely costly. Risk can be mitigated, simply by engaging an experienced commercial electrical contractor to ensure that the electrical infrastructure in your place of business is managed correctly. There should be consistency between regular maintenance activity and the longer term investment in assets. H&D Electrical provide a full service solution to ensuring continuity in supply and the continual improvement of electrical and mechanical assets.

- Exit & Emergency Light testing and repairs

- Thermal Imaging/Thermographic Scanning

- Switchboard Maintenance and Inspections

- VSD Testing & Maintenance

- Generator Testing & Maintenance

- Power Factor Correction & Voltage Optimisation

- LED Lighting

- Security Systems

- Lighting Controls

- Fault Diagnosis

- Test & Tag

- Globe & Lamp Replacements

- RCD Testing

- Compliance Inspections

- UPS Service & Testing

- Lightning Protection

Communications & Data

H&D Electrical is a preferred Technology installation and service partner in Brisbane within commercial/office applications. We work with you to understand your specific requirements and tailor a solution to suit your needs, your budget and to meet the future technology and communication demands of your business.We are able to offer design and installation of systems for both commercial and industrial applications. Whether you require a few data points, a commercial office fit-out/de-fit or a full overhaul of your existing network – H&D Electrical can work with you to provide a reliable, affordable and quality solution.

Our commitment to quality is demonstrated through our ongoing training and certification with our chosen cabling and component manufacturers. As an accredited installation partner we can provide certified warranties and peace of mind for your data and communications projects.

- Cabling Upgrades

- Design and Construct Services Cat5E, Cat6, Cat6A, Cat7 & Cat7A

- OM1, OM3 and OS1 Fibre Optic Solutions

- Carrier Lead-ins

- Installation of all Data Equipment

- CCTV Systems

- UPS Installation

Automated & Emergency Lighting | RCD Testing

Exit and Emergency lighting is a critical aspect in protecting life in the event of a fire or emergency. Exit and emergency lighting installed and maintained in accordance with AS 2293 Parts 1, 2 and 3, provides an illuminated path of egress from the building to nominated exits and emergency assembly areas.

Our Electrical technicians will address the design and installation of an emergency lighting system in a building, the system’s maintenance requirements and the performance requirements of the products that make up these emergency lighting systems.

The Standard states that a full battery discharge of each emergency and exit light must be performed every 6 months and written records of these tests must be kept. It is critical for building occupant safety that the correct type and quantity of lights are installed in the correct locations.

All testing is completed via our field technology devices and electronic reporting and certification is made available through our client interface portal.

RCD devices are sometimes known as earth leakage circuit breakers and are commonly referred to as being safety switches, but an RCD has other features and the correct RCD device must be installed in your workplace. An RCD switch should monitor the flow of electricity through the circuit it is connected to. If any faults that could lead to electrocution are detected by a functioning RCD, the device will shut off the power to the circuit in milliseconds preventing serious injury caused by electric shock.

To comply with the RCD testing requirements of AS/NZS 3760:2003 commercial workplaces must have the RCD devices tested and tagged every 6 months. This procedure is in place to ensure the RCD responds properly to any faulty situation and in the correct time frame. H&D Electrical has the expertise and latest testing equipment to carry out your scheduled RCD testing to ensure your workplace is safe and compliant.

H&D Electrical are experts in designing, installing and maintaining all types of Exit and Emergency lighting systems including:

- Central Battery Systems

- Stand Alone Single Point Units

- Nexus LX & Nexus RF computer monitored system

- Clevertronics systems

Power Factor Correction

Power Factor Correction reduces demand charges on your electricity bill and increases the load carrying capacity of your existing electrical circuits. An increasing number of our customers have engaged us to specify the size and type of PFC units required, supply a competitive quote with payback and capacity savings calculations and provide experienced installation & commissioning services.

The most effective method for improving Power factor is the installation of automatically controlled capacitor banks or ensuring your existing capacitor bank is efficient. Capacitor Banks are designed and sized to suit particular site conditions.

H&D Electrical has many years of experience in the Power Factor Correction field and is able to offer expect advice on this specialised subject. We can specify, supply, install, commission, repair, upgrade or provide maintenance on the majority of low voltage Power Factor Correction (PFC) units.

Thermal Imaging

Power Factor Correction reduces demand charges on your electricity bill and increases the load carrying capacity of your existing electrical circuits. An increasing number of our customers have engaged us to specify the size and type of PFC units required, supply a competitive quote with payback and capacity savings calculations and provide experienced installation & commissioning services.

The most effective method for improving Power factor is the installation of automatically controlled capacitor banks or ensuring your existing capacitor bank is efficient. Capacitor Banks are designed and sized to suit particular site conditions.

Thermal imaging is a valuable resource for maintaining electrical components and reducing the risk of electrical breakdowns and fire.

Using the latest in thermal imaging technology, we can find overloaded circuits before equipment fails, reducing the cost of downtime. The thermal image camera will detect heat or overloaded electrical connections known as hot spots and show early warning signs that electrical components are at risk of failure including fire and switchboard damage.

Thermal imaging for all your building’s switchboards should be carried out every 12 months and more frequently if environmental conditions are influential. Many insurance companies are now making thermal imaging a condition of policy renewal. Thermal imaging is a non-destructive defect testing technique, which means there’s no interference to your building’s power supply during a preventative maintenance check. Switchboard thermo scanning is undertaken while the equipment is on-line and running at normal capacity.

All of our inspections are performed by qualified electricians with Level 1 Thermography certification, and are accompanied by detailed reports and technical assistance to commercial, retail and industrial customers.

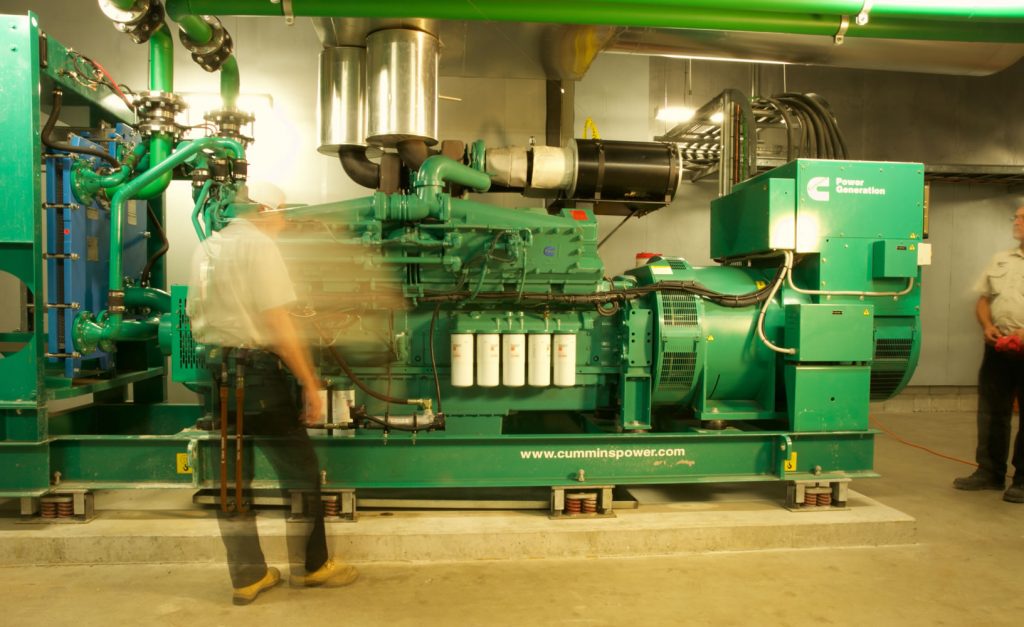

Generators

H&D Electrical is trusted with the maintenance of over 30 Generators across the Brisbane CBD market, within many A Grade and 6 star NABERS commercial buildings. We have been involved in the power generation industry for more than 30 years, and have extensive experience in the maintenance of diesel and gas generators.

Our qualified technicians are fully trained and capable across a wide range of generator models. Their skills range from expertise with diesel and gas engines through to co/tri-generation systems, generator control systems, switchboards, automatic transfer systems, fuel storage and exhaust systems.

Our service division operates 24 hours a day, 7 days a week across Brisbane to ensure your generator operates when required.

Our Generator maintenance scope of works, includes:

- Programmed scheduling based on manufacturers’ specifications recommendations and our knowledge

- Load bank units for testing generators, UPS units, switchgear and battery autonomy

- Fuel quantity testing and treatment

- Engine oil testing and analysis

Energy Management

H&D Electrical can develop and support Energy Management Strategies for building owners and Facility Managers. By utilising our experience in projects to achieve the most energy efficient electrical design, enhancing commercial building operations and tenant satisfaction. This extends into installation and programmed maintenance.

Our process involves auditing and accessing electrical usage and equipment performance, providing fully costed solutions with pay-back analysis to managing all aspects of design and installation.

We are at the forefront of technology to help you assess and optimise your systems to make sure that you meet your NABERS, BEEC and Green Star obligations. Through effective design and controlled maintenance programmes, H&D Electrical can assist in reporting and planning for optimal energy consumption based on usage patterns in facilities and offer early warning systems for preventative maintenance and extending asset lifecycles.

Examples of recent projects delivering greater efficiencies in energy consumption:

- LED and induction lighting solutions

- Lighting controls – occupancy sensors and daylight harvesting

- Building automation design and implementation

- Variable speed drives for motors and pumps

- Power Factor Correction

- Timers and motion detection

Lightning Protection Systems

A Lightning Protection System provides a conductive path between an air terminal and earth, so that when a building is struck by lightning, the majority of the lightning’s current follows the path of the Lightning Protection System, with substantially less current traveling through flammable materials.

Damage to a building occurs when high voltages travel too quickly and bypass surge protection equipment. Because lightning can send extremely high voltages into an electrical installation, arcs can jump at multiple places, which can cause mechanical damage and ignition to a building.

Lightning protection acts as a safeguard, it’s designed to protect a structure by intercepting extremely high currents of strikes and passing them safely from the structure to the ground, via a network of air terminals, conductors and ground electrodes.

Regular maintenance will ensure that, when your lightning protection system is called upon to protect your people, building and critical business assets, you have a compliant preventative maintenance program. H&D Electrical has extensive experience in both installation and maintenance of Lightning Protection Systems across several Brisbane CBD office towers.

Lightning Protection Systems are sophisticated networks. Not only does weather, such as extreme temperatures and high winds affect lighting protection equipment, but also building upgrades involving new construction, building additions, re-roofing or remodeling and changes to electrical, mechanical or communication systems can also affect a system’s performance.

Because changes are likely if not inevitable, all electrical building maintenance schedules should include annual lighting protection equipment maintenance.

Solar Energy Solutions

A Solar energy system offers an affordable solution by allowing commercial and industrial property owners the ability offset rising electricity costs by generating their own electricity on-site.

With the cost of solar systems decreasing dramatically over the last couple of years, Solar energy systems represent an excellent investment for businesses as payback periods and return on investment is now a viable proposition.

By understanding the load profile of your business operation through the day H&D Electrical is able to provide a solar energy system that is customised for your business operation.

A Solar energy system also provides your company with the opportunity to display your environmental credentials and provide a quantifiable way to show that your company is reducing its green-house gas emissions.Avoiding the sharp increases in utility electricity prices, Solar energy solutions are under warranty for long-term power production.

When engaged by our clients, we will undertake an initial assessment to determine commercial viability. Further support is provided through a detailed analysis regarding alternative load and supply scenarios; eligibility for government assistance; pre-discussion and planning with the power utility; approvals; system design; product and technology selection; installation and maintenance plan; and proposal development.

All our solar panel installers are clean energy council accredited and are fully qualified A grade electricians. You can rest assured that your solar panel system is installed with care and complies with safety requirements.